Sling Protection: Cut vs. Wear

- The number one cause of synthetic sling failure is cutting

- Lift-All offers a family of sling protection to protect both sling and load from damage

- Increases sling life

- Both Edge Defender™ and our patented Sling Shield are designed to protect sling from cutting

- Wide variety of wear pad material and styles to reduce sling abrasion

- Cut Protection Products are designed to improve workplace safety. When placed between slings and edges, cut protection products act as a buffer to prevent sling cutting and to reduce bearing pressure levels at contact areas.

- Wear protection products serve to extend sling life by reducing abrasive wear and prevent marring of the load surfaces.

| Product | Thickness | Color | Relative Cut Protection Performance Rating |

|---|---|---|---|

| CUT PROTECTION | |||

| Edge Defender™ 3-ply Polyester Quick Sleeve Code: ED |

0.45 | Yellow | |

| Edge Defender™ Flex Plus Flat Quick Sleeve w/ Dyneema® Code: FQSD |

0.35 | White/Yellow | |

| Edge Defender™ Flex Plus Tubular Quick Sleeve w/ Dyneema® Code: TQSD |

0.35 | White/Yellow | |

| Sling Shield™ Code: SS |

1" Radius | Silver/Red | |

| COMMON WEAR PROTECTION MATERIALS - LOOSE PADDING | |||

| Polyester Webbing 1600 Webmaster® Pads |

0.14 | Yellow | |

| Dyneema Sleeving (Light Duty Single Wall) |

0.054 | White | |

| Pukka (Synthetic Felt) Pads | 0.33 | White | |

| Leather (Heavy) Pads | 0.13 | Tan | |

| PVC Pads | 0.17 | Black | |

| SEWN-ON TYPE PADS | |||

| Polyester Webbing 1600 Webmaster® Pads |

0.14 | Yellow | |

| Dyneema Sleeving (Light Duty Single Wall) |

Not Recommended as a Sewn Sleeve | ||

| Pukka (Synthetic Felt) Pads | 0.33 | White | |

| Leather (Heavy) Pads | 0.13 | Tan | |

| PVC Pads | 0.17 | Black | |

Performance Rating: The bar graphs shown above reflect the comparative performance of Lift-All Cut Protection products against commonly used loose and sewn-on types of Wear Protection products.

Test Lift Qualification: To validate the suitability of sling protection products for each application, always complete one or more test lifts in a non-consequence manner. Technical Bulletin MS-10 is available for additional information.

Edge Defender™

- Cut Protection: The patented technology creates a high level of compression on the surface to produce a superior level of cut protection.

- Conforms to the Shape of Load Edges: The flat design will conform to the load shape during handling operations, yet the construction is firm enough to prevent wrinkling.

- Ease of Attachment: The use of hook and loop straps allow quick attachment and helps to hold position on slings.

Edge Defender™ Flex Plus

Flat Style Cut Protection

- The 'Flex Plus' is the addition of a double-plied layer of Dyneema with Kevlar® aramid binding.

- Thinner, lighter, and more flexible than the standard Lift-All Edge Defender yet maintain the same level of cut protection performance.

Tubular Style Cut Protection

- 360° of Protection: The Edge Defender Flex Plus tubular style pad is well-suited for use with roundslings and affords uniform cut protection around the exterior of the sling body.

- Pad Positioning: When sized properly, this tubular pad will offer protection in the desired location on slings.

Download our Edge Defender™ Flex Plus catalog Find a Distributor

Sling Shield™

- Magnetic: Holds position against steel loads for ease of rigging.

- 1" Bend Radius: The design provides a bend radius to reduce bearing pressures for synthetic slings.

- Ease of Sling Inspection: The open design allows easy access to slings during their frequent inspections.

* Ultimate rating regardless of width. Note: Lifting in a vertical hitch reduces the ratings by half.

| Product | Thickness |

|---|---|

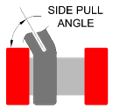

| 65° | 17,500 |

| 60° | 15,000 |

| 55° | 13,000 |

| 50° | 11,000 |

| 45° | 8,000 |

- The load rating for a Sling Shield is 25,000 lbs. of sling tension per inch of sling width. This rating is reduced when lifting at sling angles of less than 70°.

- See Safety Bulletin for more detailed information (included with each product at time of purchase).

Download our Sling Shield™ catalog Find a Distributor

Wear Protection

- Sling and Load Damage Protection: Wear Protection can help to protect both the sling and the load from wear damage.

- Construction Materials: A variety of padding materials are available to best suit the needs of each application.

- Ease of Sling Inspection: Length selection and other pad options are available that allow easy access to slings for frequent inspections.

- Ease of Attachment: Some styles use hook and loop fastening to allow quick attachment and to help keep the position on the sling.

| SLEEVE TYPE Preferred for slings that are used in a variety of lifting situations. Easily repositioned along sling body to accommodate loads of various sizes. Sleeve allows sling to adjust to lift without movement against load edge. |

||||||||

|---|---|---|---|---|---|---|---|---|

| Tubular Quick Sleeve |

|

High strength hook & loop sleeve for secure positioning. Tubular design gives maximum usable surface and maximum pad life. | ||||||

| Flat Quick Sleeve |

|

Hook & loop sleeve allow easy installation and removal. Friction keeps sleeve in place when rigging | ||||||

| Flat Sewn Sleeve |

|

Preferred for long-term use on single sling. May be repositioned as needed along sling length. May require factory installation for slings with hardware and single leg Tuflex. | ||||||

| Poly Pads |

|

Slides easily along sling length for convenient sling protection. Must be installed at factory for web slings with hardware. | ||||||

| SEWN-ON TYPE For use on web slings where repetitive lifting situations expose the sling to damage. Eliminates the need to position pad before each lift. |

||||||||

| Sewn-On Wear Pad |

|

For sling protection at expected wear points. Can be sewn anywhere on the sling, be any length and be on one or both sides. | ||||||

| Edge Guard |

|

Helps protect both edges of the sling. Placement on the sling per customer requirement. | ||||||

Wear Pad Materials

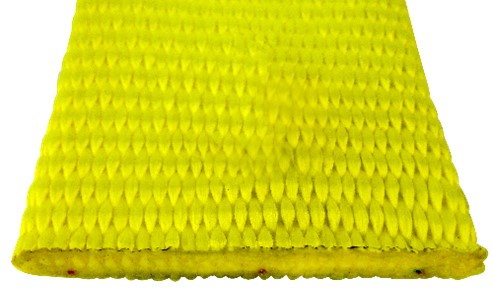

Texturized Buffer (TN) 0.09375” Thick

A bulked fiber is used to produce a thin webbing with good abrasion resistance.

Ballistic Nylon (BN) 0.0625” Thick

A 2-ply wear-resistant fabric made of bulked nylon fiber, appropriate for wider sleeves.

Download our Wear Protection catalog Find a Distributor