Roundslings

The Tuflex® Difference

What is a Tuflex Roundsling?

All Lift-All® roundslings meet or exceed OSHA and ASME B30.9 standards and regulations. A Tuflex roundsling is an endless synthetic sling made from a continuous loop polyester yarn covered by a double-wall tubular jacket. The synthetic roundsling body can also be compared to sling webbing with the tubular jacket face yarns woven without binder yarns; this allows the core yarns to move independently within the jacket.

Lift up to 1 million pounds with Lift-All’s KeyFlex™ Ultra High-Performance roundslings. Lift-All provides a solution for lifting your heaviest loads using the lightest, most flexible, and ergonomic polyester slings available, our high-performance roundslings. DynaFlex™ and KeyFlex Roundslings offer peace of mind when lifting your heaviest loads.

The Stage Rigging Roundslings, also part of the high-performance roundsling category, provide solutions for lighting and stage rigging suspension. Whether choosing SteelFlex™ Roundslings with the steel galvanized aircraft cable core or the Black Polyester Stage Slings, you can be ready for curtain call with Lift-All stage rigging roundslings.

- Tuflex® Roundslings

- Direct Connect Hook

- High-Performance Roundslings

- DynaFlex™

- KeyFlex™

- KeyFlex™ Ultra

- SteelFlex™ Roundslings

- Black Stage Slings

Tuflex Roundslings

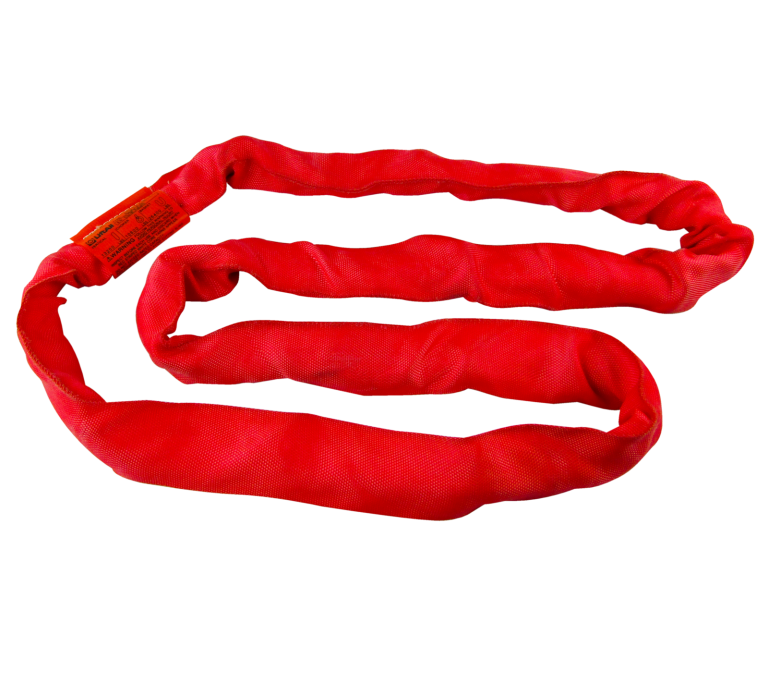

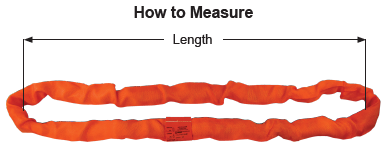

Tuflex Endless Roundslings

The most versatile Tuflex roundsling.

- Load stability and balance can be achieved by spreading sling legs.

- Wear points can be shifted to extend sling life.

- The most flexible style of sling.

- Individual slings can be attached together using appropriate hardware, see Direct Connect Hooks section.

Tuflex Eye/Eye Roundslings

A more rugged and durable Tuflex Roundsling.

- An additional jacket of texturized, abrasion resistant nylon covers the Tuflex body forming two color-coded lifting eyes.

Tuflex Bridle Roundslings

Better load control and balance when fixed lifting points are available.

- Use of hardware prevents cutting and abrasion of sling at bearing points.

- Reduces damage by protecting load between pick-up point and crane hook.

- Lightweight and pliable for easy rigging and storage.

- Sling hooks quickly connect to loads having hoist rings or eye bolts.

Tuflex Braided Roundslings

For multi-part heavy lifting, braided Tuflex roundslings offer you additional security.

Tuflex braids are made from three (6-Part), or four (8-Part) individual Tuflex roundslings. Should one of these component slings be damaged while in use, the remaining undamaged slings will be able to assist in safely returning the load to the ground.

- Braided construction offers engineered safety.

- Lightweight and more flexible than chain slings.

- Easy to transport and hook-up.

- 6-part flat braid offers wide-body for load stability.

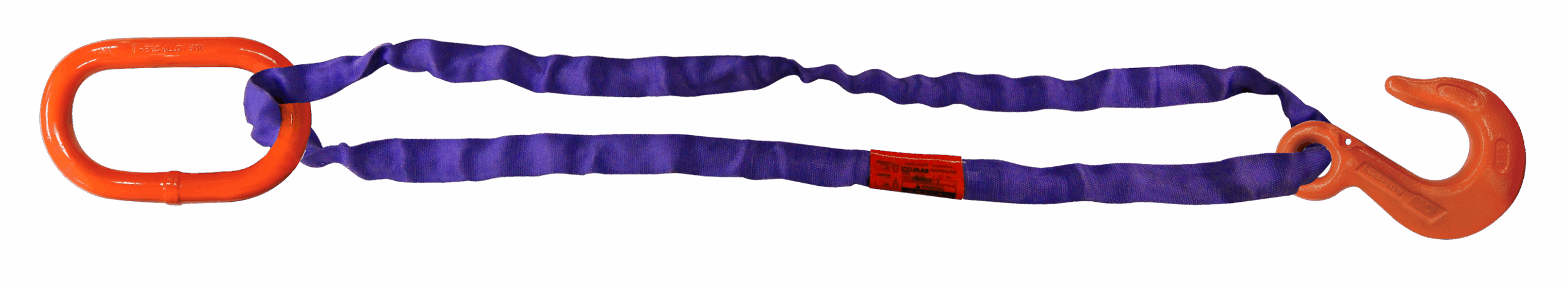

Direct Connect Hooks

Direct Connect hooks are the quickest and easiest way to add hooks to Tuflex® roundslings and web slings at your job site. No tools or extra parts are needed.

Direct Connect hooks are the quickest and easiest way to add hooks to Tuflex® roundslings and web slings at your job site. No tools or extra parts are needed.For Tuflex slings, just match the color-coded hook to the same color Tuflex sling, and you are ready to go. Rated capacities are the same for both the hook and the Tuflex roundsling.

- Rugged: The alloy steel hook and latch are forged for superior toughness.

- Color-coded hook matches Tuflex color and capacity.

- Web-Trap™ design keeps sling in place, ready to use.

- Four hook sizes to match Tuflex sizes EN30 (Purple), EN60 (Green), EN90 (Yellow) and EN150 (Red).

- Can be used with 1″ and 2″ web slings.

- Quick connections with no tools needed.

- Increases the life of the sling by reducing wear at the bearing point.

Part Number Color Rated Capacity (lbs.) Tuflex Web Slings Width Plies DCH1 Purple 2,600 EN30 1 1 DCH2 Green 5,300 EN60 1 2 DCH3 Yellow 8,400 EN90 2 1 & 2 DCH4 Red 13,200 EN150 – – High-Performance Roundslings

The solution for lifting the heaviest loads using the lightest, most flexible, and ergonomic slings available!

The Lift-All Difference

The Lift-All Difference – Why compromise work safety? Here’s why all high-performance roundslings are not the same:

- Load-Bearing Core Yarn: Non-blended core fibers provide more consistent sling performance, regardless of the application.

- Verified Strength: Lift-All regularly completes strength verification of all sizes of roundslings using test pins that are smaller than required by the industry to represent actual loading conditions more closely.

- Single Path Core is Our Standard: Multi-path slings exhibit an advantage during strength verification testing as test pins allow for tension forces to be spread over a wider, flat bearing surface. Our single path round design fits naturally in narrow, rounded bearing surfaces of connection hardware. We designed our high performance roundslings with the understanding of how the sling is used in the field. This is validated during strength verification testing.

- The Cover Sleeve: Roundslings are typically removed from service due to cover wear. Lift-All‘s design contains a durable, double layer cover that offers rotational benefits for even wear and ease of feeding through connections.

DynaFlex

DynaFlexDyneema® High-Performance Core Ultra-Lightweight Roundsling

DynaFlex is manufactured with a load bearing core of Dyneema, the world’s strongest fiber, yet remains soft and flexible to allow for easy rigging. This high capacity, ultra-lightweight roundsling is a safe and ergonomic alternative to steel and other forms of synthetic slings.

- Ultra-Lightweight – Approximately 20% lighter than KeyFlex™ and 52% lighter than Tuflex for the same capacity, reducing the probabilities of hand and shoulder strains and sprains.

- Neutral Buoyancy – DynaFlex slings are a great choice for water recovery and lifting applications.

- 100% Dyneema Core (non-blended) – We use the most advanced high tenacity fiber on the market for lifting slings. The homogeneous core fiber reacts uniformly regardless of lift application. Designed with your safety in mind.

KeyFlex

KeyFlex- Low weight per capacity reduces risk of injury to riggers.

- Great for low headroom situations.

- 1% stretch at rated capacity reduces abrasion and allows for better load control.

- KeyFlex with aramid load fiber is approved for use up to 350°F.

- Lightweight and compact size promote speedier rigging, transport and storage when compared to any other type of sling.

KeyFlex Ultra Roundslings

KeyFlex Ultra RoundslingsThe Higher Capacity KeyFlex Roundsling

- High Capacities: Up to 1/2 million pounds in a vertical hitch, or 1 million pounds in a basket hitch.

- Rugged Construction: Our best 4-ply Tufhide™ nylon jacket covers three individual KeyFlex roundslings with Technora®

- High Value: You get the Lift-All quality you expect which exceeds industry standards at a competitive price.

- Extra Utility: KeyFlex Ultra roundslings can be returned to Lift-All for disassembly, inspection, and re-tagging as individual slings.

- Repairable: The outer cover can be replaced.

- KeyFlex Ultra is 87% lighter than comparable capacity wire rope slings.

Part Number Rated Capacity (lbs.) Vertical Choker Basket @ 90° Basket @ 45° KEN3P200 200,000 160,000 400,000 280,000 KEN3P250 250,000 200,000 500,000 350,000 KEN3P300 300,000 240,000 600,000 420,000 KEN3P400 400,000 320,000 800,000 560,000 KEN3P500 500,000 400,000 1,000,000 780,000  SteelFlex Roundslings

SteelFlex RoundslingsThe steel sling with the fabric feel.

With safety being of the utmost importance in overhead suspension, Lift-All’s SteelFlex roundslings combine flexibility, strength and heat resistance (400°F) with the soft feel of fabric to meet your most demanding suspension requirements.

SteelFlex roundslings feature steel galvanized aircraft cable wound in an endless configuration. This wire core is encased in a black double-wall, polyester jacket. A unique inspection window allows for easy inspection of the core for broken wires and corrosion. The result is a highly flexible, easy to use sling that complies with all of the current rigging codes. Stretch at rated capacity is approximately 1%.

- No backup rigging required.

- Engineered window allows for core inspection.

- Superior flexibility makes rigging easy.

- Conforms to the load to grip securely.

- Superior cut resistance.

Part Numbers Rated Capacity (lbs.) Vertical Choker Basket GACEN60CX18IN 5,300 4,200 10,600 GACEN60CX2 GACEN60CX3 GACEN60CX4 GACEN60CX5 GACEN60CX6 GACEN60CX7 GACEN60CX8 GACEN60CX9 GACEN60CX10 GACEN60CX11 GACEN60CX12  Black Stage Slings

Black Stage SlingsThese lightweight roundslings are ideal for easy and inconspicuous suspension of stage sound and lighting equipment. Black sleeve material helps sling blend into the surroundings. Lift-All® stage slings include all of the Tuflex® features and benefits except that the color coding of the slings is achieved by using a color-coded identification tag. Double-wall sleeve material is standard.

- Ideal for stage sound and lighting equipment.

- Black sleeve material helps sling blend into the surroundings.

- Color-coded identification tag.

- Double-wall sleeve material is standard.

Part Numbers Color of Tags Rated Capacity (lbs.) Vertical Choker Basket BSEN30 Purple 2,600 2,100 5,200 BSEN60 Green 5,300 4,200 10,600 BSEN90 Yellow 8,400 6,700 16,800